On Oct. 5, 2022, NASA’s SpaceX Crew-5 mission successfully launched four astronauts to the International Space Station, where they will take advantage of the microgravity environment to conduct “more than 200 science experiments and technology demonstrations.” These experiments have the potential to significantly improve life on Earth, according to NASA.

Behind every meaningful mission like the Crew-5, there are not only hundreds of people who help pull off a successful launch but also hundreds of scientists who make research in space a reality. Many of them are located here, in the Florida High Tech Corridor’s 23-county region.

For more than 25 years, The Corridor’s Matching Grants Research Program (MGRP) has fueled the creation of new intellectual property and the commercialization of breakthrough technologies in efforts to position Florida as a global aerospace industry leader. By matching industry investments in collaborative research with the University of Central Florida (UCF) – “America’s Space University” – and the University of South Florida (USF), the MGRP multiplies the capabilities of local companies.

Matching grants are a cost-effective way for aerospace industry partners to access the expertise of renowned university researchers with specific industry expertise. They also create opportunities for students to participate in hands-on research, inspiring them to pursue related careers and helping them form relationships with future employers.

These projects model what’s possible when the region’s innovative business and academic communities collaborate to address industry’s most difficult challenges.

Optical Imaging Estimates Cryogenic Oxygen Tank Volumes

Cryogenic fluids – gasses stored at temperatures so cold they transform to liquid – are critical to space exploration. Applications are diverse, from rocket propulsion to power generation using fuel cells to providing a source of oxygen in harsh environments.

UCF postdoctoral scholar Zheyuan Zhu and Ph.D. candidate Andrew Klein conduct research for the MGRP collaboration with ETA Space.

NASA has dedicated significant resources to research in producing, storing and using these precious and hazardous materials. In 2020, NASA awarded more than $250 million to companies developing cryogenic fluid management technologies, including $27 million to Eta Space, a Merritt Island company founded in 2019 by former NASA engineers.

“Nobody has ever stored cryogenic propellants in space for more than several hours and there are new technologies that need to be developed and tested,” said Jack Fox, project manager for the Eta Space LOXSAT mission. “UCF is providing us with a critical technology for an orbital fuel gauge that we will be demonstrating on orbit in 2024.”

Eta Space’s multiyear effort to develop a complete cryogenic oxygen fluid management system sparked its partnership with Sean Pang, Ph.D., assistant professor in the College of Optics and Photonics at UCF, postdoctoral scholar Zheyuan Zhu and Ph.D. candidate Andrew Klein.

Supported by a grant of more than $67,000 from The Corridor’s MGRP, the partners are creating optical imaging technology to help astronauts estimate the mass of liquid available in liquid oxygen storage tanks. Think of it like the meter on a gas tank, but in zero-gravity environments where the stakes are much higher.

“From imaging to communication, optical technologies have been playing key roles in information acquisition and transmission. With help from the MGRP, we are able to support graduate students who are helping solve challenging problems in the space industry with optics, especially with the leading experts in cryogenic fluid management technology at Eta Space,” said Pang.

Keep exploring: Check out this video of NASA moving the liquid oxygen tank (LOX), which sits atop the hydrogen tank in Artemis.

Microscope Alternatives Maximize Scientific Research in Space

Life science researchers and engineers alike relish the chance to conduct experiments in the microgravity of low-Earth orbit and on the International Space Station because of its unique effects on materials, fluids and biological systems that cannot be replicated on Earth. However, one crucial limitation in space-based research and/or manufacturing is the limited availability of physical space, mass, and weight permitted in-flight or on-station. This creates challenges for translating research approaches or procedures from on-the-ground to in-space activities. The consequence is often a reduced number of samples or read-outs because the hardware is too large and can only handle a limited number of samples.

[L-R] UCF postdoctoral scholar Mahmoud Omer, imec’s Dr. Veerle Reumers and UCF aerospace engineering M.S. student Sylvain Le Henaff celebrate progress on their MGRP research collaboration.

Nano and digital technology innovators at Kissimmee’s imec addressed this challenge with the development of its lens-free imaging (LFI) microscope – an extremely compact, low-cost, easy-to-use alternative to traditional microscopes. Combining sensor technology and holographic imaging, imec’s technology can be automated to study cells, tissues, particles, and more as needed for scientists and engineers. It allows for significantly more samples to be monitored with much larger fields of view, while minimizing the required physical real estate.

“With both imec and UCF located in Central Florida, it made sense for us to collaborate,” said Veerle Reumers, Ph.D., research and development manager at imec USA. “Imec hosted three UCF students at our NeoCity site so they could learn all about imec technologies, and we transferred our protocols to them. This benefitted the research project and will hopefully also boost their careers. The scientific discussions with Dr. Coathup and Dr. Kinzel are always inspiring, and the collaboration during this project has already led to several other project proposal submissions. We selected Dr. Coathup to work on this project because of her many years of experience and impressive track record in bone regeneration research. Dr. Kinzel was selected for his expertise in computational fluid dynamics and aerodynamics. We appreciate the integrity of both these well-established researchers.”

In collaboration with Michael Kinzel, Ph.D., assistant professor of mechanical and aerospace engineering, and Melanie Coathup, Ph.D., professor of medicine at UCF, imec is now working to integrate its LFI microscopes with the Space Tango CubeLab. The integration minimizes the physical real estate required for imaging, maximizing space available for samples and other data collection systems.

This work was made possible by a matching grant of almost $140,000 from The Corridor, which allowed not only for access to expert faculty, but also for the participation of students in hands-on research, including:

- Sylvain Le Henaff, Aerospace Engineering M.S. student

- Sebastian Lopez, Aerospace Engineering M.S. student

- Taylor Peterson, Aerospace Engineering Ph.D. candidate

- Mahmoud Omer, College of Medicine postdoctoral scholar

- Juanpablo Delgado, Aerospace Engineering B.S. student

“These funds enabled students to adapt on-the-ground research experiments to automated experiments using imec’s compact LFI microscope,” said Kinzel.

CubeSats Improving Global Communications

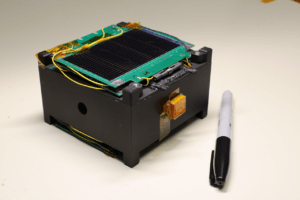

In January 2021, the SpaceX Transporter-1 mission set a world record for the most satellites launched into space on a single mission. USF Institute of Applied Engineering (IAE) students and faculty engineered three of them.

The CubeSat developed by USF students is roughly the size of a permanent marker.

The record-breaking satellite launch was a culmination of the partnership between USF and the U.S. Special Operations Command innovation incubator, SOFWERX, which started in 2017. IAE researchers designed the softball-sized cubic satellites, called “CubeSats,” to develop technology for a networked communications platform in space. Ultimately, the goal was to enable secure, real-time communications anywhere around the globe.

The Corridor’s MGRP provided several awards throughout the process to galvanize the partnership with SOFWERX, and accelerate progress in research and development. Led by IAE President and CEO Robert Bishop, and Senior Research Engineer Peter Jorgensen, Ph.D., 24 USF graduate and undergraduate students participated in the multiyear effort. Among the undergraduate students involved, multiple students were inspired to pursue a master’s degree based on their involvement in the project.

More recently, USF’s IAE won $200,000 in NASA’s TechLeap Prize competition, a feat made possible by the team’s interest and research in the space domain.

“This success can be traced back to the knowledge and experience the team gained while executing the space technology R&D project work supported by The Corridor,” said Jorgensen.

Keep exploring: Read more about the satellites engineered by USF IAE students and faculty that launched on a world-record mission.

Patentable Aluminum Coatings Withstand Harsh Environments

Clearwater-based Freedom Metal Finishings has supplied aerospace giants, such as Lockheed Martin, Northrop Grumman, Honeywell and Boeing, with finishing solutions since the days of moon missions in the 1960s. Among its service offerings, aluminum anodizing is a popular method in which the metal is coated with a special film to prevent damage in space’s extreme environmental conditions.

USF mechanical engineering student Enrique Hernandez-Jurado conducts research in MGRP collaboration with Freedom Metal Finishings.

While NASA’s Materials International Space Station Experiment and similar research initiatives have produced many advancements in material coatings since the 1960s, additional research is required to meet the needs of modern missions to the moon and Mars.

Freedom is collaborating with Christopher Alexander, Ph.D., assistant professor in the USF Department of Civil & Environmental Engineering, to validate and improve technology from Freedom’s own research and development facility. Their research explores a new process for forming oxide films to reduce aluminum corrosion that can be manufactured in a fraction of the time of traditional methods.

The Corridor’s MGRP distributed $50,000 in matching funds, allowing two USF engineering students to participate in the research.

“Through this work, one of the students graduated with his master’s degree in materials science and engineering. He has since worked as an intern at GE Aviation and now works as a materials and process engineer at Northrup Grumman in their additive manufacturing group,” said Alexander. “The students have gained immense practical experience that they are leveraging into career opportunities.”

Keep exploring: Learn more about Freedom Metal Finishings’ historic connection to the space industry.

Get Involved in Space Research

Learn more about how to take advantage of The Corridor’s MGRP.